how to know what the bolt pattern and offset is on wheels

Wheel Bolt Pattern is the measured diameter of an imaginary circumvolve formed by the centers of the bike studs or bolt holes. Mutual bolt patterns have 4, 5, vi, or 8 lug holes, while less mutual take 3, 7, or 10 lug commodities patterns.

Interchangeable Wheel / Bolt Pattern Chart for Cars, Trucks, Vans, SUVs, Motorhomes, RVs, ATVs, UTVs and Trailers

This cantankerous reference database was created to help you hands discover a particular vehicle bolt blueprint, and to identify other vehicles with wheels that volition fit yours.

Wheel Bolt Design by Brand and Model

Vehicle Commodities Pattern Specifications In This Cross Reference:

- 3 Lug

- 4 lug

- 5 Lug

- 6 Lug

- 7 Lug

- 8 Lug

- 10 Lug

3 Lug Bolt Patterns:

- 3 Ten 70

- 3 Ten ninety

- 3 Ten 100

- 3 10 112

- 3 X 120

A 3 Lug Commodities Design or Pitch Circle Diameter (PCD) is made upwardly of the stud count ( iii ) and the bolt circle measurement , the notional circumvolve determined by the center position of the studs.

A 3 Lug Commodities Design or Pitch Circle Diameter (PCD) is made upwardly of the stud count ( iii ) and the bolt circle measurement , the notional circumvolve determined by the center position of the studs.

Learn more than virtually wheel dimensions.

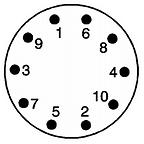

Bolt Design Torque Sequence / Specifications:

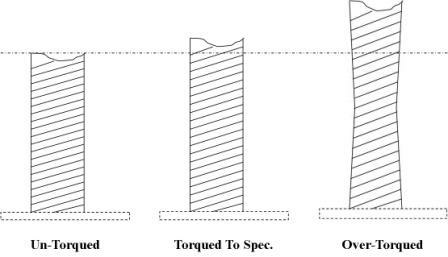

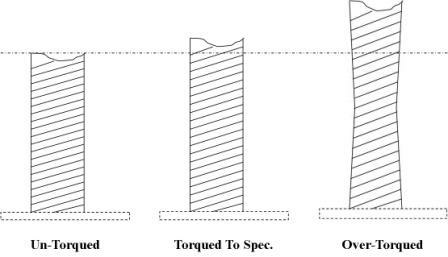

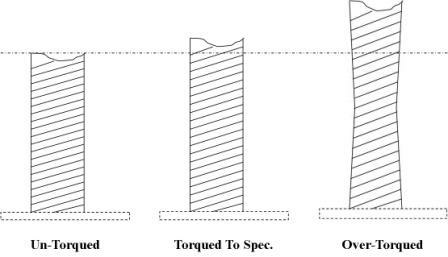

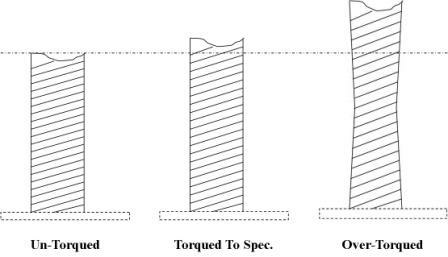

Note: Alloy wheels should always be installed using a torque wrench ensuring proper mount. Bank check your vehicle owner manual for proper specifications. How To Properly Torque Lug Nuts / Lug Bolts

| Stud Size | Typical Torque Range in Ft/Lbs | Minimum Thread Date (turns) |

| 12 10 one.5 mm | 70 - fourscore | 6.5 |

| 12 x 1.25 mm | 70 - eighty | eight |

| 14 x 1.five mm | 85 - xc | seven.5 |

| 14 x 1.25 mm | 85 - xc | 9 |

| 7/xvi in. | 70 - lxxx | 8 |

| 1/two in. | 75 - 85 | 8 |

| 9/xvi in. | 135 - 145 | 8 |

It is prudent to re-torque wheels subsequently about 60 to ninety miles (100km to 150km) of driving. Learn more most lug nuts and torque.

Wheels, Spacers and Adapters

Wheel Spacers ~ Adapters ~ Wheels

Trailer Bike Commodities Patterns

Most recreational and utility trailers on the road today accept a 4, 5 or 6 lug bolt design, while heavy-duty trailers volition most often apply 6, viii or x lug wheels.

The most common trailer wheel bolt design overall is five 10 4.v and is also a very popular size in rider cars.

Automobile makers such as Ford, Mercury, Dodge, Jeep, Mazda, Lexus, Toyota, Honda, Acura and others use 5 X 4.5 wheels, which as well makes this a very popular commodities pattern in aftermarket wheels.

Other trailer bolt patterns are listed beneath, with links to vehicles with matching bolt blueprint.

Small-scale Trailer Wheel Bolt Patterns:

- four 10 4 (nearly common)

- 4 Ten nine.44

Travel Trailer and Utility Trailer Wheel Bolt Patterns:

- five Ten 4.five (about common)

- 5 X five

- 5 X 5.5

Heavy-Duty Trailer Bicycle Bolt Patterns:

- 6 10 5.v (common)

- viii Ten 275

- viii X half-dozen.5 (common)

- ten X 8.75

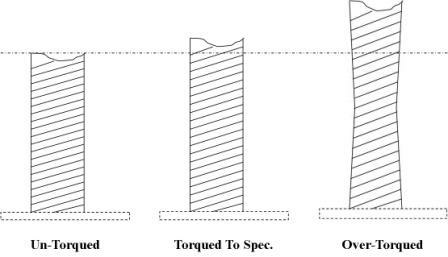

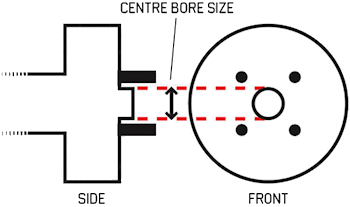

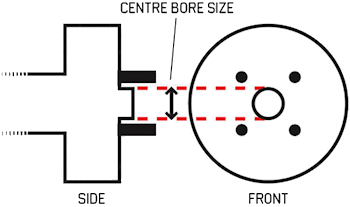

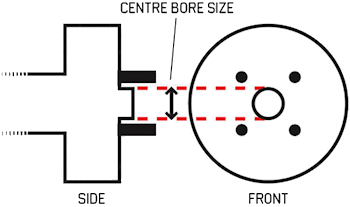

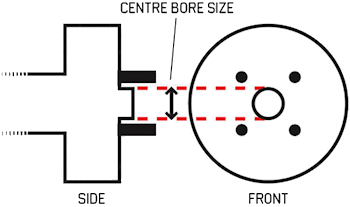

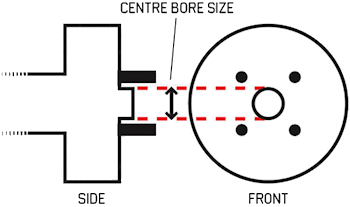

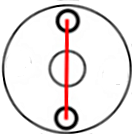

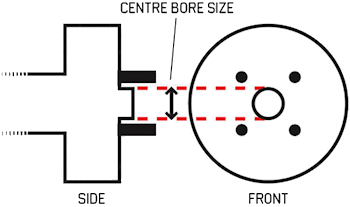

Wheel Hub Eye Bore

Hub Center Bore: Relates to the center hole in the cycle that centers the wheel on the hub of the automobile. Since near wheels are mass produced, they have a large heart bore to accommodate several unlike vehicles. If this is the case, it is recommended that you use a hub ring. Hub rings are hard plastic or metal ring that fits betwixt the bicycle and the vehicle. This centers the bike perfectly on the hub ensuring that there is no run out when the cycle is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the bike / tire assembly is perfectly balanced.

Hub Center Bore: Relates to the center hole in the cycle that centers the wheel on the hub of the automobile. Since near wheels are mass produced, they have a large heart bore to accommodate several unlike vehicles. If this is the case, it is recommended that you use a hub ring. Hub rings are hard plastic or metal ring that fits betwixt the bicycle and the vehicle. This centers the bike perfectly on the hub ensuring that there is no run out when the cycle is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the bike / tire assembly is perfectly balanced.

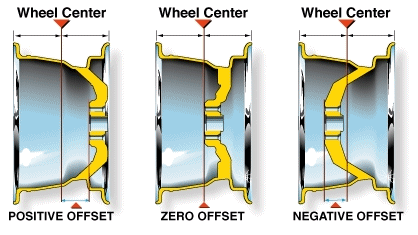

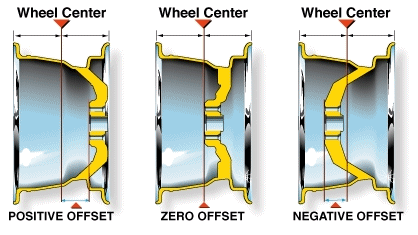

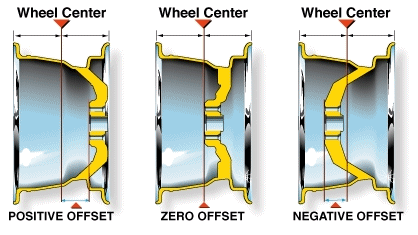

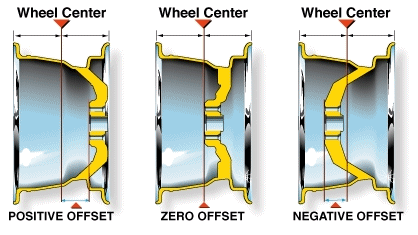

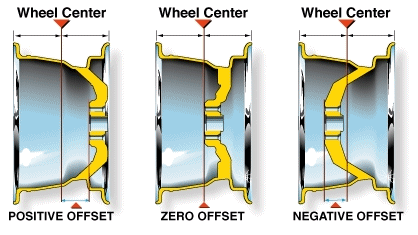

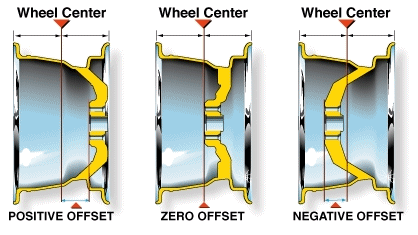

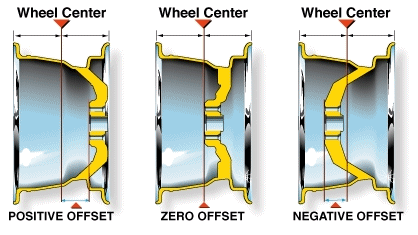

Wheel First

Wheel offset is the distance from the mounting surface of the bike to the true eye line of the rim. A positive kickoff ways the mounting surface of the wheel is positioned in front of the true center line of the rim / tire assembly. This in upshot brings the tire in to the fender well more than. Conversely, a negative offset ways the mounting surface of the wheel is behind the true centre line of the rim / tire associates. This volition cause the tire to stick out abroad from the vehicle.

H = High - Positive First, typically FWD (Front Wheel Drive) +45, 40, 35 offsets

Grand = Medium - Neutral Offset, typically RWD (Rear Bike Drive) +20 starting time

L = Low - Nada to Negative Outset, Offset typically RWD (Rear Wheel Bulldoze) 0 offset

4 Lug Bolt Patterns:

- 4 X 85

- 4 10 90

- 4 Ten 98

- 4 X 100

- 4 10 108 (4 X 4.25)

- 4 X 110

- 4 X 112

- iv X 115

- four X 130

- 4 X 137

- four Ten 140

- four 10 143

- 4 X 144

- 4 X 150

- 4 X 156

- iv X 166

- 4 X iii.75

- iv Ten iv

- iv 10 iv.25 (iv Ten 108)

- 4 X four.5 (4 X 114.3)

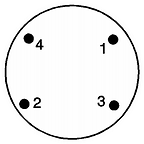

A 4 Lug Bolt Pattern or Pitch Circle Bore (PCD) is made upward of the stud count ( iv ) and the bolt circle measurement , the notional circle adamant by the middle position of the studs.

A 4 Lug Bolt Pattern or Pitch Circle Bore (PCD) is made upward of the stud count ( iv ) and the bolt circle measurement , the notional circle adamant by the middle position of the studs.

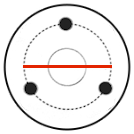

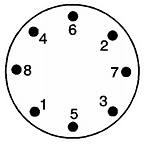

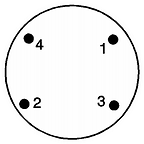

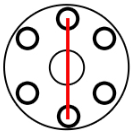

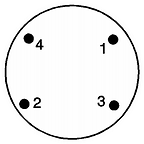

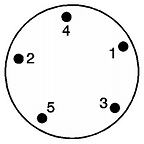

How To Measure four Lug Bolt Patterns

Mensurate four lug bike bolt patterns from center to center distance betwixt ii studs that are beyond the hub from each other. This measurement is your commodities pattern bore. Learn more about bicycle dimensions.

Bolt Blueprint Torque Sequence / Specifications:

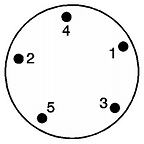

Bolt Design Torque Sequence Specifications: 1, iii, 2, four

Annotation: Alloy wheels should e'er be installed using a torque wrench ensuring proper mount. Cheque your vehicle owner manual for proper specifications. How To Properly Torque Lug Nuts / Lug Bolts

| Stud Size | Typical Torque Range in Ft/Lbs | Minimum Thread Engagement (turns) |

| 12 x one.5 mm | seventy - 80 | 6.5 |

| 12 x 1.25 mm | 70 - 80 | 8 |

| xiv x ane.5 mm | 85 - ninety | 7.5 |

| 14 ten one.25 mm | 85 - ninety | nine |

| seven/16 in. | 70 - lxxx | 8 |

| 1/2 in. | 75 - 85 | 8 |

| 9/16 in. | 135 - 145 | 8 |

It is prudent to re-torque wheels later on virtually 60 to 90 miles (100km to 150km) of driving. Learn more nearly lug nuts and torque.

Wheels, Spacers and Adapters

Wheel Spacers ~ Adapters ~ Wheels

Trailer Bike Bolt Patterns

Most recreational and utility trailers on the road today have a 4, v or 6 lug commodities design, while heavy-duty trailers will most often utilize 6, 8 or 10 lug wheels.

The near common trailer wheel bolt pattern overall is five X 4.five and is also a very popular size in passenger cars.

Car makers such as Ford, Mercury, Contrivance, Jeep, Mazda, Lexus, Toyota, Honda, Acura and others use v X 4.v wheels, which also makes this a very pop bolt pattern in aftermarket wheels.

Other trailer commodities patterns are listed below, with links to vehicles with matching bolt pattern.

Small Trailer Bicycle Bolt Patterns:

- four 10 4 (most common)

- 4 X 9.44

Travel Trailer and Utility Trailer Bicycle Bolt Patterns:

- five Ten 4.5 (nigh mutual)

- 5 X v

- 5 X 5.v

Heavy-Duty Trailer Bicycle Commodities Patterns:

- 6 X 5.5 (common)

- 8 X 275

- eight X six.v (common)

- x Ten 8.75

Bike Hub Center Diameter

Hub Center Bore: Relates to the center hole in the wheel that centers the wheel on the hub of the car. Since most wheels are mass produced, they accept a large center bore to suit several different vehicles. If this is the instance, information technology is recommended that you apply a hub ring. Hub rings are difficult plastic or metal ring that fits betwixt the bicycle and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the wheel / tire associates is perfectly balanced.

Hub Center Bore: Relates to the center hole in the wheel that centers the wheel on the hub of the car. Since most wheels are mass produced, they accept a large center bore to suit several different vehicles. If this is the instance, information technology is recommended that you apply a hub ring. Hub rings are difficult plastic or metal ring that fits betwixt the bicycle and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the wheel / tire associates is perfectly balanced.

Wheel Offset

Wheel offset is the altitude from the mounting surface of the wheel to the true center line of the rim. A positive start means the mounting surface of the wheel is positioned in forepart of the true center line of the rim / tire assembly. This in result brings the tire in to the fender well more. Conversely, a negative offset ways the mounting surface of the bicycle is behind the true center line of the rim / tire assembly. This will cause the tire to stick out away from the vehicle.

H = Loftier - Positive Showtime, typically FWD (Front Wheel Drive) +45, 40, 35 offsets

One thousand = Medium - Neutral Offset, typically RWD (Rear Bicycle Drive) +20 offset

Fifty = Low - Zero to Negative Offset, Offset typically RWD (Rear Wheel Drive) 0 kickoff

five Lug Bolt Patterns:

- 5 Ten 98

- 5 X 100

- five X 105

- 5 X 108 (5 X 4.25)

- 5 X 110

- v Ten 112

- 5 X 115

- 5 X 120

- 5 X 127 (5 X 5)

- v Ten 130

- 5 X 135

- 5 Ten 150

- v X 155

- v X 205

- 5 10 4

- 5 X 4.25 (5 X 108)

- 5 X four.5 (v Ten 114.3)

- 5 10 4.75

- 5 X 5 (five X 127)

- 5 10 five.5

- 5 X 6.5

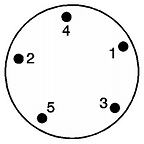

A 5 Lug Bolt Pattern or Pitch Circle Diameter (PCD) is made up of the stud count ( v ) and the bolt circle measurement , the notional circumvolve determined past the center position of the studs.

A 5 Lug Bolt Pattern or Pitch Circle Diameter (PCD) is made up of the stud count ( v ) and the bolt circle measurement , the notional circumvolve determined past the center position of the studs.

How To Mensurate 5 Lug Commodities Patterns

Mensurate 5 lug bicycle commodities patterns from the outside edge to center altitude betwixt two studs that are across the hub from each other. This measurement is your commodities blueprint diameter. Learn more about wheel dimensions.

Bolt Pattern Torque Sequence / Specifications:

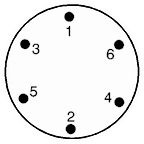

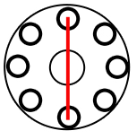

Bolt Design Torque Sequence Specifications: 1, 3, v, ii, 4

Note: Alloy wheels should always exist installed using a torque wrench ensuring proper mountain. Check your vehicle owner manual for proper specifications. How To Properly Torque Lug Nuts / Lug Bolts

| Stud Size | Typical Torque Range in Ft/Lbs | Minimum Thread Appointment (turns) |

| 12 x 1.five mm | lxx - lxxx | 6.5 |

| 12 10 1.25 mm | 70 - 80 | 8 |

| 14 x 1.v mm | 85 - ninety | 7.five |

| 14 x i.25 mm | 85 - 90 | 9 |

| 7/16 in. | 70 - 80 | eight |

| 1/2 in. | 75 - 85 | viii |

| 9/16 in. | 135 - 145 | viii |

It is prudent to re-torque wheels after about threescore to 90 miles (100km to 150km) of driving. Acquire more most lug nuts and torque.

Wheels, Spacers and Adapters

Bicycle Spacers ~ Adapters ~ Wheels

Trailer Bicycle Bolt Patterns

Most recreational and utility trailers on the road today accept a four, five or six lug bolt pattern, while heavy-duty trailers volition nigh often use 6, 8 or 10 lug wheels.

The most common trailer bicycle commodities pattern overall is 5 Ten 4.5 and is also a very popular size in passenger cars.

Machine makers such equally Ford, Mercury, Contrivance, Jeep, Mazda, Lexus, Toyota, Honda, Acura and others use 5 X 4.5 wheels, which also makes this a very popular bolt pattern in aftermarket wheels.

Other trailer commodities patterns are listed below, with links to vehicles with matching bolt design.

Small Trailer Wheel Bolt Patterns:

- 4 Ten iv (near common)

- 4 X ix.44

Travel Trailer and Utility Trailer Cycle Bolt Patterns:

- five 10 4.5 (most mutual)

- v X 5

- 5 10 5.five

Heavy-Duty Trailer Cycle Bolt Patterns:

- 6 X 5.five (common)

- 8 10 275

- 8 X six.5 (common)

- ten X 8.75

Wheel Hub Center Diameter

Hub Center Diameter: Relates to the center hole in the wheel that centers the wheel on the hub of the car. Since most wheels are mass produced, they have a big middle bore to accommodate several different vehicles. If this is the example, it is recommended that y'all use a hub ring. Hub rings are hard plastic or metal ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the cycle is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the wheel / tire assembly is perfectly balanced.

Hub Center Diameter: Relates to the center hole in the wheel that centers the wheel on the hub of the car. Since most wheels are mass produced, they have a big middle bore to accommodate several different vehicles. If this is the example, it is recommended that y'all use a hub ring. Hub rings are hard plastic or metal ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the cycle is installed on to the vehicle. Without hub rings it is possible to get vibrations even if the wheel / tire assembly is perfectly balanced.

Wheel Offset

Wheel beginning is the distance from the mounting surface of the cycle to the truthful center line of the rim. A positive showtime means the mounting surface of the cycle is positioned in front of the true center line of the rim / tire assembly. This in event brings the tire in to the fender well more than. Conversely, a negative starting time ways the mounting surface of the wheel is behind the true center line of the rim / tire assembly. This volition cause the tire to stick out abroad from the vehicle.

H = High - Positive Starting time, typically FWD (Front Wheel Drive) +45, xl, 35 offsets

One thousand = Medium - Neutral Commencement, typically RWD (Rear Bicycle Drive) +20 offset

L = Low - Nix to Negative Offset, Offset typically RWD (Rear Wheel Drive) 0 offset

6 Lug Bolt Patterns:

- half-dozen X 115

- 6 Ten 127

- 6 X 132

- vi X 135

- half dozen X 4.5

- vi X 5

- 6 X 5.5

- six Ten 8.75

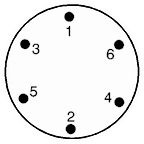

A six Lug Bolt Design or Pitch Circle Bore (PCD) is made upwardly of the stud count ( vi ) and the bolt circle measurement , the notional circle determined by the center position of the studs.

A six Lug Bolt Design or Pitch Circle Bore (PCD) is made upwardly of the stud count ( vi ) and the bolt circle measurement , the notional circle determined by the center position of the studs.

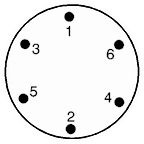

How To Measure 6 Lug Bolt Patterns

Measure 6 lug wheel bolt patterns from center to center distance between 2 studs that are across the hub from each other. This measurement is your commodities pattern diameter. Learn more most wheel dimensions.

Commodities Pattern Torque Sequence / Specifications:

Bolt Pattern Torque Sequence Specifications: 1, half-dozen, 4, 2, five, iii

Annotation: Alloy wheels should always be installed using a torque wrench ensuring proper mount. Check your vehicle owner manual for proper specifications. How To Properly Torque Lug Nuts / Lug Bolts

| Stud Size | Typical Torque Range in Ft/Lbs | Minimum Thread Engagement (turns) |

| 12 x 1.v mm | 70 - 80 | 6.5 |

| 12 x 1.25 mm | lxx - 80 | viii |

| 14 x ane.5 mm | 85 - 90 | 7.v |

| 14 10 i.25 mm | 85 - 90 | 9 |

| 7/16 in. | 70 - 80 | 8 |

| 1/2 in. | 75 - 85 | 8 |

| 9/sixteen in. | 135 - 145 | 8 |

It is prudent to re-torque wheels subsequently well-nigh 60 to 90 miles (100km to 150km) of driving. Learn more well-nigh lug nuts and torque.

Wheels, Spacers and Adapters

Wheel Spacers ~ Adapters ~ Wheels

Trailer Bicycle Bolt Patterns

Nearly recreational and utility trailers on the road today take a four, 5 or half dozen lug bolt blueprint, while heavy-duty trailers will most oftentimes use 6, eight or 10 lug wheels.

The most common trailer wheel bolt design overall is 5 X four.5 and is also a very popular size in passenger cars.

Car makers such as Ford, Mercury, Dodge, Jeep, Mazda, Lexus, Toyota, Honda, Acura and others use 5 X 4.5 wheels, which also makes this a very pop bolt pattern in aftermarket wheels.

Other trailer bolt patterns are listed below, with links to vehicles with matching bolt pattern.

Small Trailer Wheel Bolt Patterns:

- four X iv (most common)

- 4 X nine.44

Travel Trailer and Utility Trailer Wheel Commodities Patterns:

- 5 10 4.five (near common)

- 5 X v

- 5 X 5.five

Heavy-Duty Trailer Cycle Bolt Patterns:

- vi X v.5 (common)

- 8 X 275

- 8 X 6.5 (common)

- 10 10 viii.75

Bike Hub Center Bore

Hub Centre Diameter: Relates to the center pigsty in the bicycle that centers the wheel on the hub of the car. Since most wheels are mass produced, they accept a large center bore to arrange several different vehicles. If this is the example, information technology is recommended that you use a hub ring. Hub rings are hard plastic or metallic ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the cycle is installed on to the vehicle. Without hub rings information technology is possible to get vibrations fifty-fifty if the cycle / tire assembly is perfectly balanced.

Hub Centre Diameter: Relates to the center pigsty in the bicycle that centers the wheel on the hub of the car. Since most wheels are mass produced, they accept a large center bore to arrange several different vehicles. If this is the example, information technology is recommended that you use a hub ring. Hub rings are hard plastic or metallic ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that there is no run out when the cycle is installed on to the vehicle. Without hub rings information technology is possible to get vibrations fifty-fifty if the cycle / tire assembly is perfectly balanced.

Wheel Outset

Wheel offset is the altitude from the mounting surface of the wheel to the truthful eye line of the rim. A positive offset ways the mounting surface of the wheel is positioned in forepart of the truthful center line of the rim / tire assembly. This in upshot brings the tire in to the fender well more than. Conversely, a negative offset ways the mounting surface of the wheel is behind the true middle line of the rim / tire assembly. This will cause the tire to stick out away from the vehicle.

H = High - Positive Offset, typically FWD (Front Wheel Bulldoze) +45, xl, 35 offsets

M = Medium - Neutral Offset, typically RWD (Rear Bicycle Drive) +xx offset

50 = Low - Nix to Negative Offset, Showtime typically RWD (Rear Bicycle Drive) 0 offset

7 Lug Bolt Design:

- 7 X 150

The seven X 150 Lug Bolt Pattern or Pitch Circle Diameter (PCD) is made up of the stud count ( 7 ) and the commodities circumvolve measurement ( 150 ), the notional circle determined past the center position of the studs.

The 7 X 150 bolt pattern was only used by Ford. There are no other vehicles that use a 7 lug commodities pattern. The 7 Lug wheel option was part of Ford'southward HD Payload Package. Instead of measureing the commodities circumvolve, simply count the lugs. Larn more than about wheel dimensions.

Bolt Design Torque Sequence / Specifications:

Notation: Alloy wheels should always be installed using a torque wrench ensuring proper mount. Bank check your vehicle owner manual for proper specifications. How To Properly Torque Lug Basics / Lug Bolts

| Stud Size | Typical Torque Range in Ft/Lbs | Minimum Thread Engagement (turns) |

| 12 x 1.five mm | lxx - lxxx | half dozen.5 |

| 12 10 1.25 mm | 70 - 80 | 8 |

| 14 x one.v mm | 85 - ninety | 7.5 |

| 14 x 1.25 mm | 85 - xc | 9 |

| 7/xvi in. | 70 - 80 | eight |

| i/2 in. | 75 - 85 | 8 |

| 9/16 in. | 135 - 145 | eight |

It is prudent to re-torque wheels afterward near 60 to xc miles (100km to 150km) of driving. Larn more than about lug nuts and torque.

Wheels, Spacers and Adapters

Bicycle Spacers ~ Adapters ~ Wheels

Trailer Wheel Bolt Patterns

Near recreational and utility trailers on the road today take a 4, five or 6 lug bolt design, while heavy-duty trailers will most often use 6, viii or ten lug wheels.

The most mutual trailer cycle commodities blueprint overall is 5 X 4.5 and is also a very pop size in rider cars.

Car makers such as Ford, Mercury, Dodge, Jeep, Mazda, Lexus, Toyota, Honda, Acura and others use 5 10 4.5 wheels, which also makes this a very popular commodities blueprint in aftermarket wheels.

Other trailer bolt patterns are listed below, with links to vehicles with matching bolt pattern.

Small-scale Trailer Wheel Bolt Patterns:

- 4 X iv (most common)

- 4 X nine.44

Travel Trailer and Utility Trailer Bicycle Bolt Patterns:

- five X 4.5 (nearly common)

- 5 Ten five

- v X five.5

Heavy-Duty Trailer Bike Bolt Patterns:

- half dozen X v.5 (mutual)

- 8 X 275

- viii X 6.5 (common)

- 10 Ten 8.75

Wheel Hub Center Bore

Hub Center Bore: Relates to the center hole in the bike that centers the wheel on the hub of the motorcar. Since nearly wheels are mass produced, they take a big center bore to adapt several unlike vehicles. If this is the example, it is recommended that y'all use a hub band. Hub rings are hard plastic or metal ring that fits betwixt the wheel and the vehicle. This centers the cycle perfectly on the hub ensuring that in that location is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to become vibrations even if the wheel / tire assembly is perfectly counterbalanced.

Hub Center Bore: Relates to the center hole in the bike that centers the wheel on the hub of the motorcar. Since nearly wheels are mass produced, they take a big center bore to adapt several unlike vehicles. If this is the example, it is recommended that y'all use a hub band. Hub rings are hard plastic or metal ring that fits betwixt the wheel and the vehicle. This centers the cycle perfectly on the hub ensuring that in that location is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to become vibrations even if the wheel / tire assembly is perfectly counterbalanced.

Wheel Showtime

Wheel first is the distance from the mounting surface of the wheel to the true centre line of the rim. A positive offset means the mounting surface of the wheel is positioned in front of the true center line of the rim / tire assembly. This in effect brings the tire in to the fender well more. Conversely, a negative offset means the mounting surface of the wheel is behind the true center line of the rim / tire assembly. This volition crusade the tire to stick out abroad from the vehicle.

H = High - Positive Offset, typically FWD (Front Wheel Drive) +45, 40, 35 offsets

M = Medium - Neutral Offset, typically RWD (Rear Cycle Drive) +20 showtime

50 = Low - Zip to Negative Offset, Beginning typically RWD (Rear Bike Drive) 0 offset

8 Lug Bolt Patterns:

- eight X 170

- 8 10 200

- viii X 225

- 8 X 275

- 8 10 6.5

A 8 Lug Bolt Pattern or Pitch Circumvolve Diameter (PCD) is made upward of the stud count ( 8 ) and the commodities circumvolve measurement , the notional circle adamant by the heart position of the studs.

A 8 Lug Bolt Pattern or Pitch Circumvolve Diameter (PCD) is made upward of the stud count ( 8 ) and the commodities circumvolve measurement , the notional circle adamant by the heart position of the studs.

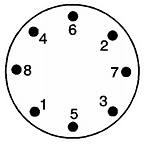

How To Measure 8 Lug Bolt Patterns

Measure out 8 lug wheel bolt patterns from center to center distance between ii studs that are across the hub from each other. This measurement is your bolt blueprint diameter. Learn more nigh wheel dimensions.

Bolt Pattern Torque Sequence / Specifications:

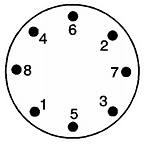

Commodities Pattern Torque Sequence Specifications: 1, 8, 4, 6, 2, seven, 3, 5

Note: Blend wheels should always be installed using a torque wrench ensuring proper mount. Check your vehicle possessor manual for proper specifications. How To Properly Torque Lug Nuts / Lug Bolts

| Stud Size | Typical Torque Range in Ft/Lbs | Minimum Thread Engagement (turns) |

| 12 x 1.5 mm | seventy - 80 | 6.v |

| 12 ten 1.25 mm | 70 - 80 | 8 |

| fourteen x 1.5 mm | 85 - 90 | 7.5 |

| 14 10 1.25 mm | 85 - 90 | ix |

| vii/xvi in. | 70 - 80 | 8 |

| i/2 in. | 75 - 85 | eight |

| ix/16 in. | 135 - 145 | 8 |

It is prudent to re-torque wheels after about threescore to 90 miles (100km to 150km) of driving. Larn more about lug nuts and torque.

Wheels, Spacers and Adapters

Wheel Spacers ~ Adapters ~ Wheels

Trailer Wheel Bolt Patterns

Well-nigh recreational and utility trailers on the road today take a four, 5 or half dozen lug bolt design, while heavy-duty trailers will nigh often use 6, eight or 10 lug wheels.

The most common trailer wheel bolt pattern overall is 5 10 4.5 and is as well a very popular size in passenger cars.

Machine makers such every bit Ford, Mercury, Contrivance, Jeep, Mazda, Lexus, Toyota, Honda, Acura and others use five X 4.v wheels, which also makes this a very popular commodities pattern in aftermarket wheels.

Other trailer commodities patterns are listed beneath, with links to vehicles with matching commodities pattern.

Small Trailer Wheel Bolt Patterns:

- 4 X four (most common)

- 4 10 nine.44

Travel Trailer and Utility Trailer Wheel Bolt Patterns:

- 5 X 4.5 (almost mutual)

- v X v

- 5 Ten five.5

Heavy-Duty Trailer Bike Bolt Patterns:

- half dozen X 5.5 (common)

- 8 X 275

- 8 X half dozen.5 (common)

- 10 X eight.75

Wheel Hub Center Bore

Hub Center Diameter: Relates to the middle hole in the wheel that centers the bicycle on the hub of the auto. Since most wheels are mass produced, they accept a large center bore to accommodate several different vehicles. If this is the case, it is recommended that you utilize a hub ring. Hub rings are difficult plastic or metal band that fits between the wheel and the vehicle. This centers the bicycle perfectly on the hub ensuring that there is no run out when the bike is installed on to the vehicle. Without hub rings information technology is possible to go vibrations even if the wheel / tire assembly is perfectly balanced.

Hub Center Diameter: Relates to the middle hole in the wheel that centers the bicycle on the hub of the auto. Since most wheels are mass produced, they accept a large center bore to accommodate several different vehicles. If this is the case, it is recommended that you utilize a hub ring. Hub rings are difficult plastic or metal band that fits between the wheel and the vehicle. This centers the bicycle perfectly on the hub ensuring that there is no run out when the bike is installed on to the vehicle. Without hub rings information technology is possible to go vibrations even if the wheel / tire assembly is perfectly balanced.

Wheel Kickoff

Wheel offset is the distance from the mounting surface of the wheel to the true centre line of the rim. A positive offset ways the mounting surface of the bicycle is positioned in front end of the true center line of the rim / tire assembly. This in effect brings the tire in to the fender well more. Conversely, a negative offset ways the mounting surface of the wheel is behind the true center line of the rim / tire assembly. This will cause the tire to stick out away from the vehicle.

H = High - Positive Offset, typically FWD (Forepart Wheel Drive) +45, twoscore, 35 offsets

M = Medium - Neutral Offset, typically RWD (Rear Wheel Drive) +xx offset

L = Low - Goose egg to Negative Showtime, Offset typically RWD (Rear Wheel Drive) 0 offset

ten Lug Bolt Patterns:

- 10 X 225

- 10 X 7.25

- 10 Ten xi.25

A 10 Lug Bolt Pattern or Pitch Circle Diameter (PCD) is made upward of the stud count ( 10 ) and the commodities circle measurement , the notional circle determined by the center position of the studs.

A 10 Lug Bolt Pattern or Pitch Circle Diameter (PCD) is made upward of the stud count ( 10 ) and the commodities circle measurement , the notional circle determined by the center position of the studs.

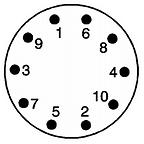

How To Measure 10 Lug Commodities Patterns

Measure ten lug cycle commodities patterns from centre to center distance between 2 studs that are across the hub from each other. This measurement is your bolt pattern diameter. Learn more than nearly cycle dimensions.

Commodities Blueprint Torque Sequence / Specifications:

Bolt Design Torque Sequence Specifications: 1, 6, 8, 4, ten, 2, v, 7, 3, nine

Annotation: Alloy wheels should always be installed using a torque wrench ensuring proper mount. Check your vehicle owner manual for proper specifications. How To Properly Torque Lug Nuts / Lug Bolts

| Stud Size | Typical Torque Range in Ft/Lbs | Minimum Thread Appointment (turns) |

| 12 x 1.five mm | 70 - 80 | half dozen.5 |

| 12 x 1.25 mm | 70 - 80 | eight |

| xiv 10 i.v mm | 85 - xc | 7.five |

| fourteen x 1.25 mm | 85 - xc | 9 |

| 7/16 in. | seventy - 80 | 8 |

| 1/2 in. | 75 - 85 | eight |

| nine/sixteen in. | 135 - 145 | viii |

It is prudent to re-torque wheels after nigh 60 to xc miles (100km to 150km) of driving. Learn more about lug nuts and torque.

Wheels, Spacers and Adapters

Wheel Spacers ~ Adapters ~ Wheels

Trailer Wheel Bolt Patterns

Most recreational and utility trailers on the road today accept a 4, 5 or vi lug bolt blueprint, while heavy-duty trailers will nearly often apply 6, 8 or 10 lug wheels.

The most common trailer cycle bolt pattern overall is 5 X 4.v and is also a very popular size in passenger cars.

Car makers such as Ford, Mercury, Dodge, Jeep, Mazda, Lexus, Toyota, Honda, Acura and others apply five X four.five wheels, which also makes this a very popular bolt blueprint in aftermarket wheels.

Other trailer bolt patterns are listed below, with links to vehicles with matching bolt blueprint.

Small Trailer Wheel Bolt Patterns:

- 4 X 4 (well-nigh common)

- iv X 9.44

Travel Trailer and Utility Trailer Wheel Bolt Patterns:

- five Ten iv.v (almost mutual)

- 5 X five

- 5 X v.5

Heavy-Duty Trailer Wheel Commodities Patterns:

- 6 10 v.5 (common)

- 8 X 275

- 8 X 6.5 (common)

- x Ten viii.75

Wheel Hub Heart Bore

Hub Center Diameter: Relates to the center pigsty in the wheel that centers the bike on the hub of the car. Since nigh wheels are mass produced, they have a large center bore to adjust several different vehicles. If this is the case, it is recommended that you utilise a hub ring. Hub rings are hard plastic or metal ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that at that place is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to become vibrations even if the bicycle / tire assembly is perfectly counterbalanced.

Hub Center Diameter: Relates to the center pigsty in the wheel that centers the bike on the hub of the car. Since nigh wheels are mass produced, they have a large center bore to adjust several different vehicles. If this is the case, it is recommended that you utilise a hub ring. Hub rings are hard plastic or metal ring that fits between the wheel and the vehicle. This centers the wheel perfectly on the hub ensuring that at that place is no run out when the wheel is installed on to the vehicle. Without hub rings it is possible to become vibrations even if the bicycle / tire assembly is perfectly counterbalanced.

Bike Get-go

Wheel starting time is the distance from the mounting surface of the wheel to the true eye line of the rim. A positive offset ways the mounting surface of the wheel is positioned in front of the true middle line of the rim / tire assembly. This in consequence brings the tire in to the fender well more than. Conversely, a negative get-go means the mounting surface of the cycle is behind the truthful center line of the rim / tire associates. This will cause the tire to stick out away from the vehicle.

H = High - Positive Offset, typically FWD (Front Wheel Drive) +45, 40, 35 offsets

Yard = Medium - Neutral Outset, typically RWD (Rear Wheel Bulldoze) +xx offset

L = Low - Zilch to Negative Kickoff, Showtime typically RWD (Rear Cycle Drive) 0 offset

Jump to Manufacturer Commodities Patterns and Bike Sizes

ATV / UTV / Power Sport Bolt Patterns:

Rider Car / Truck Commodities Patterns:

RV / Charabanc / Commercial Truck Commodities Patterns:

Browse Wheels past Rim Size (Bolt Design, Diameter, Width)

How To & DIY

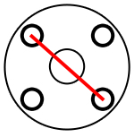

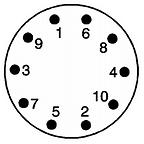

How To Measure Wheel Bolt Pattern

The bolt pattern, or bolt circumvolve, is the diameter of an imaginary circle formed past the centers of the wheel lugs. Common bolt patterns have 4, 5, vi, or 8 lug holes. These diagrams show the proper measuring methods for each lug count. [More than...]

How To & DIY

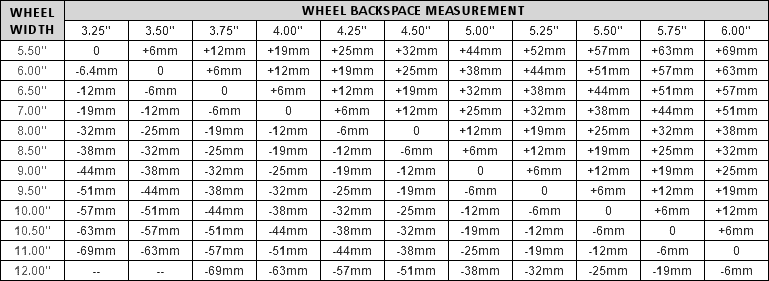

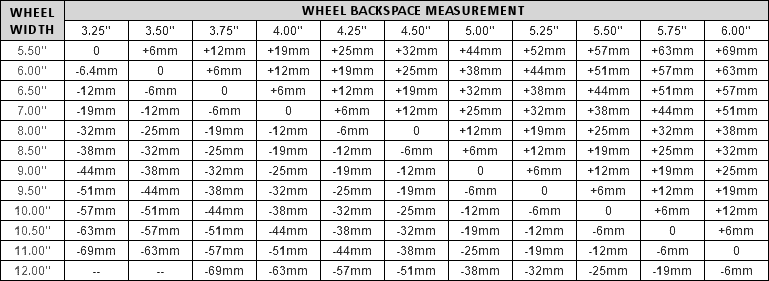

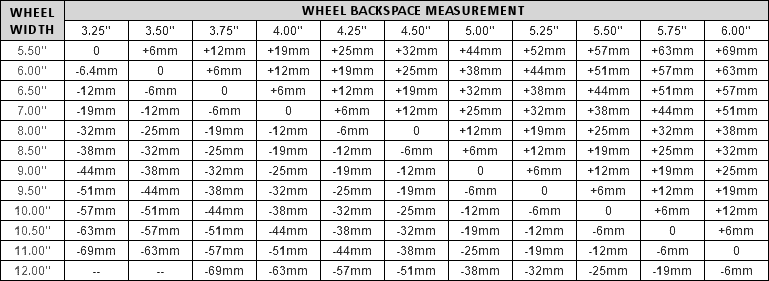

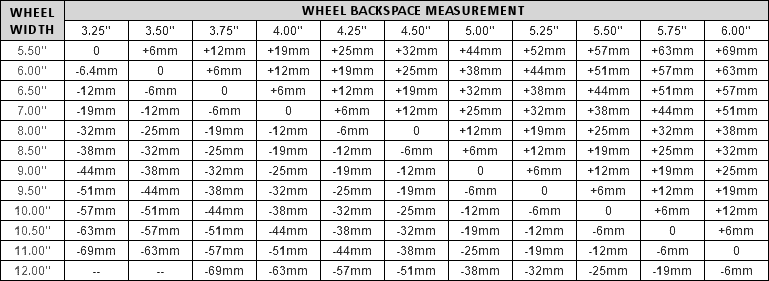

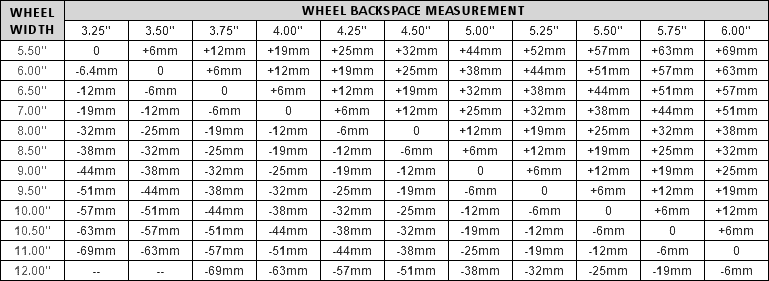

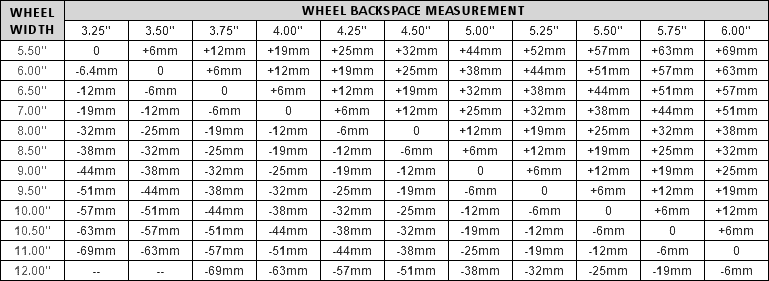

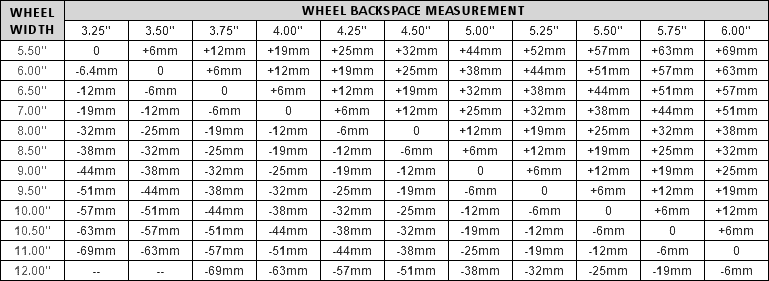

How To Measure Wheel Back Spacing / First

Back Spacing is a measurement taken from within the within of the rear side of the cycle. This measurement is important to be certain you have proper wheel clearance for your specific car before purchasing new wheels, wheel spacers and wheel adapters. [More...]

How To & DIY

How To Re-Drill Axles/Brakes For Different Bolt Blueprint Wheels

This bicycle bolt pattern drill guide jig will help you lot drill out both your axle and brake drum or brake rotor to a dissimilar bolt pattern. [More...]

How To & DIY

How To Plus Size Wheels and Tires

Plus Sizing your bicycle and tire combination was designed to enhance vehicle performance and appearance by allowing fitment of larger diameter rims and lower profile tires. The theory is that while making these changes, you lot keep the overall tire bore inside 3% of the original equipment tires. [More than...]

How To & DIY

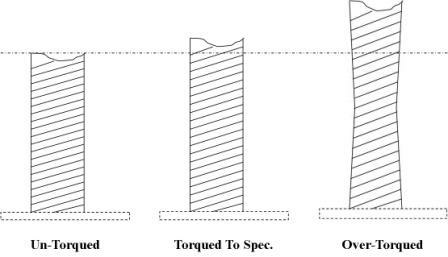

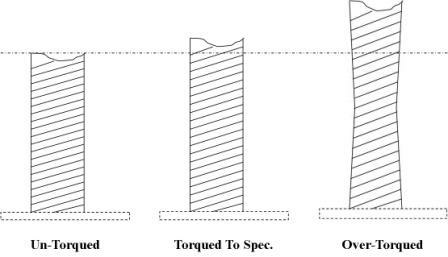

How To Properly Torque Lug Nuts / Lug Bolts

Over the years, we've seen wheels come off and much worse, all for 1 simple reason � they failed to properly torque (tighten) the lug nuts on their vehicles. Torquing lug nuts to the right torque specs and in the correct torque sequence is critical. Learn how to properly torque your lug nut / lug bolts hither. [More...]

How To & DIY

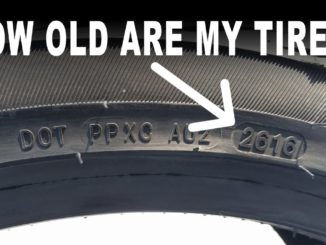

How To Determine The Historic period Of Your Tires

Accept you e'er wondered, but how old are my tires? Well, here'southward how to determine the historic period of your tires. [More than...]

Technical Info

Tire Size Guide: Radials, Poly/Fibers, Bias-Ply'due south, Cheater and Dragster Slicks

A comprehensive list of Radials, Poly/Fibers, Bias-Ply'due south, Cheater Slicks and Dragster Slicks — each original tire size is listed — and each of the related measurements is charted. [More...]

Automotive Basics

Tire Size? How To Read A Tire Sidewall

The side of your tire — known every bit the tire sidewall — contains all of the data you need to know well-nigh your tire size. Regardless of the manufacturer, all tires are required to show [More...]

Additional Wheel / Measurement Data

Key Identifying Cycle Dimensions: Wheel Bolt or Lug Pattern (or bolt circle, lug circle, lug pattern, etc.) is the measured diameter of an imaginary circle formed by the centers of the wheel lugs or commodities holes. Bolt patterns tin can be three, 4, 5, 6, 7, viii or 10 lug holes. A bolt circle of five ten 4.v would betoken a 5 lug commodities pattern on a circumvolve with a diameter of 4.5 inches.

Key Identifying Cycle Dimensions: Wheel Bolt or Lug Pattern (or bolt circle, lug circle, lug pattern, etc.) is the measured diameter of an imaginary circle formed by the centers of the wheel lugs or commodities holes. Bolt patterns tin can be three, 4, 5, 6, 7, viii or 10 lug holes. A bolt circle of five ten 4.v would betoken a 5 lug commodities pattern on a circumvolve with a diameter of 4.5 inches.

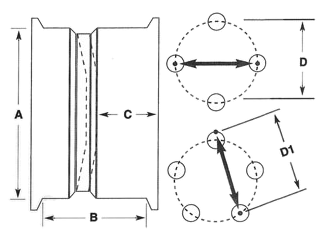

Wheel Dimensions

There are four important measurements that are used to categorize and identify a bike for fitment purposes.

- Rim Diameter The actual bore of the wheel at the point where the tire bead seats (Not the outer lip of the rim).

- Rim Width Measure from the inside of the outer lip at the bead seating point to the inner lip.

- Back Spacing From the inside of the wheel at the betoken where it contacts the hub, brake drum or axle flange to the within border (lip) of the wheel.

- Bolt Pattern The measured bore of an imaginary circle formed by the centers of the wheel lugs or commodities holes.

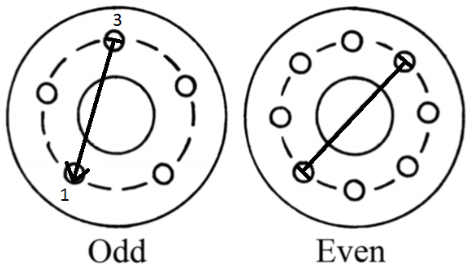

How To Measure Wheel Bolt Blueprint

If there is an Even number of lugs: Measure out center-to-centre on lugs straight beyond from each other.

If at that place is an ODD number of lugs: Measure out from the Middle of one lug to the OUTER Edge of the pigsty diagonally across from information technology.

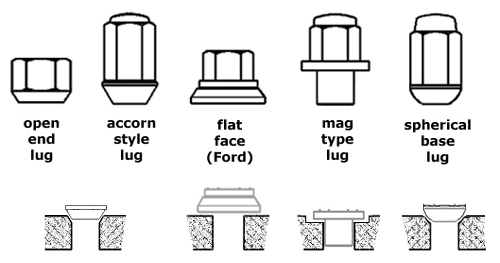

Lug Nut Types

Common Bolt Design Conversions

See Also:

- How to Mensurate Bolt Pattern Bolt design - diameter of an imaginary circle formed by the centers of the wheel lugs.

- Wheel Lug Nut / Bolt Torque Sequence Correct Wheel Lug Nut / Bolt Torque Sequence - 4 lug, five lug, 6 lug.

- How to Measure Wheel Back Spacing This measurement is important to be sure you lot have proper wheel clearance.

- How To Read A Tire Sidewall Learn to sympathise the common markings establish on tire sidewalls.

- How To Plus Size Your Wheels

- Wheel, Tire and Fender Fitment Estimator Calculate Wheel Fitment, Tire Stretch and Rolling Radius. Includes Speedometer Error Calculator. Play with specs, try different settings and combinations, compare results.

- Tire Size Modify / Speedometer Scale Figurer This reckoner is designed to give data related to tire size changes and the general bear on they accept on the calibration of a speedometer. Information technology determines speedometer error and tire size information based on published and generally accepted tire dimensions as given by the standard The states tire system (i.e. 205/45-ZR16). All calculations are based on the assumption of a new tire (equally opposed to used) where the numbers on the tire accurately represent the dimensions.

Source: https://www.roadkillcustoms.com/wheel-bolt-pattern-cross-reference/

0 Response to "how to know what the bolt pattern and offset is on wheels"

Post a Comment